A strong development trend in the automotive field is to integrate more display screens into the interior space of the vehicle, and use ultra-thin materials to provide complex shape design and clear image quality. In addition to adding functions, printing electronic devices are also embedded in the display structure to meet the needs of designers.

UV curing technology has been widely known and accepted in the printing field. It realizes more functions through polymer materials and traditional materials to provide enhanced perception space inside the vehicle. But in the past, it put more emphasis on function. Compared with any time before, film material providers are being asked to provide not only optical films, but also functional films to unlock the free-form design concept of interior space.

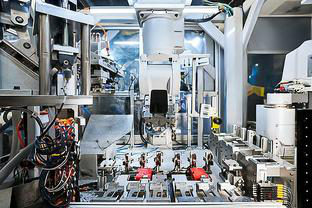

This overview will explore how to use traditional tools such as LED, UV and excimer (172nm) in series and in parallel as a fully integrated hybrid curing system for the production of functional films.

As more functional features are added to the display screen, this brings some material challenges. Traditional display materials, such as ITO (indium tin oxide), have the characteristics that are not suitable for this application, that is, brittleness. This is a known problem with ITO coatings on PET films because they tend to produce microcracks when bending, leading to faults and defects.

Modern display screens are usually composed of nine layers of such high-tech functional films. These films are assembled from an ultraviolet activated adhesive. The adhesive is usually transparent, which not only provides strong and lasting adhesion with the required optical properties, but also forms a moisture-proof protective sealing effect and can resist the degradation of sunlight at the same time. These adhesives will cure due to the corresponding UVA output provided by the LED. Due to the flexibility of high-tech display films, they are also used for indoor and environmental lighting to increase atmosphere and other feelings.

The key to making all three technologies work effectively in one architecture is to accurately monitor and control the process. The complete integration of all three light sources (excimer, led and UV) enables this hybrid platform to be widely used in other market areas, such as flooring and furniture, or hand / touch scenes. The LED / UV duet has been used in the graphic printing industry for many years, and excimer / UV is also used in graphic conversion applications. The key is that these radiation sources are not new technologies; Only through more process control, and as more materials and media for these radiation curing systems are developed, they are organically combined. Complex and intelligent application solutions require seamless interaction and cooperation.

With the deepening of the concept of hybrid application, we have seen the emergence of flexible solar cells, batteries, sensors, intelligent lighting products, medical diagnosis (and drug delivery) equipment, intelligent packaging, and even clothing! Moreover, according to the current material development trend, in the near future, we will begin to see more applications using carbon nanotubes and graphene. In the medium term, metamaterials, metallized glass and foam materials will also emerge. The true hybrid platform will become an integral part of these frontier production processes.

Post time: Apr-14-2022